Copyright 2026 © 台灣伊佐股份有限公司

All Rights Reserved.

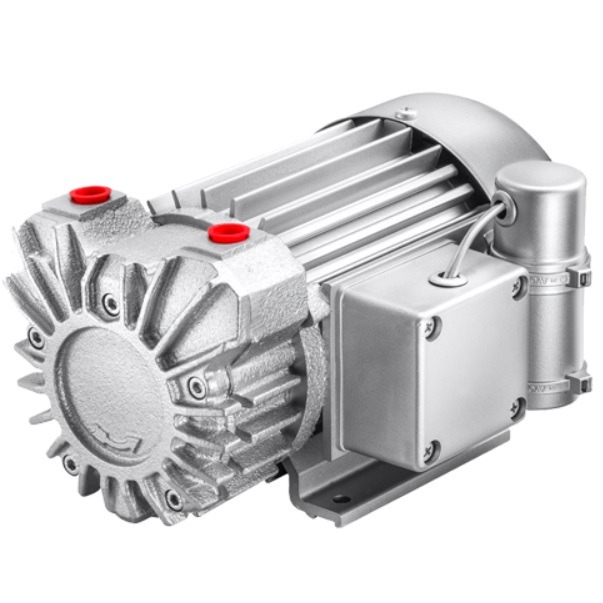

Common pump types for vacuum machines

A dry pump is a type of vacuum pump that operates without the need for lubricants (such as oil).

The primary advantage of dry pumps is that they prevent contaminants from being introduced into the vacuum system. This makes them particularly suitable for applications requiring high cleanliness standards, such as semiconductor manufacturing, optical thin film coating, and other high-tech industries.

Here are some key features and types of dry pumps:

Oil-sealed pumps have several characteristics that may vary depending on the pump type and application. Below are some common features of oil-sealed pumps:

Lubrication – Oil-sealed pumps use oil as a lubricant to reduce friction between internal moving parts, ensuring smooth operation.

Sealing – The lubricating oil also helps seal internal components, preventing gas or liquid leakage, especially in high-pressure or high-vacuum applications.

Cooling – Oil serves as a cooling medium, helping to dissipate heat and prevent overheating, particularly in high-power applications.

Extended lifespan – Proper lubrication extends the pump’s lifespan by reducing wear and the risk of mechanical failure.

Adsorption – In certain vacuum applications, oil can adsorb gas molecules, contributing to improved vacuum performance.

High performance – Some oil-sealed pumps excel in high-pressure, high-flow, and high-vacuum applications, delivering stable and reliable performance.

However, it is important to note that oil-sealed pumps also have drawbacks.

The primary concern is the potential introduction of oil molecules or particulates into the processed gas or liquid, which may be unacceptable in applications requiring high precision and cleanliness.

We use cookies to collect and analyze information on site performance and usage. By Clicking "Continue" or by clicking into any content on this site, you agree to allow cookies to be placed. To find out more, please visit our privacy policy。

CONFIRM